High Temp Heavy Duty Box Furnace

High Temp Heavy Duty Box Furnace

These furnaces are used for a variety of heat treating applications such as tempering, hardening, sintering or firing, including those applications requiring higher temperatures. Precision microprocessor based temperature controls and energy-saving insulation maximize the performance of these rugged units.

High Temp Heavy Duty Box Furnace Model Specifications:

Not for use with flammable solvents, vapors, or gases.

| Model | Workspace | Outside Dimensions*(WxDxH) | Max Temp | Heat Input | Insulation Thickness | Operating Characteristics† | Door Type | Height w/ Door Open | Hearth Rating | Approx Shipping Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions(WxDxH) | VolumeCu Ft | ElectricKW | GasBTU/HR | Control Accuracy | Temperature Uniformity | Rise Time (Electric) | Rise Time (Gas) | ||||||||

| HD-183618-HT | 18" x 36" x 18" | 6.8 | 59" x 81" x 77" | 2,200°F | 40 | 425,000 | 11" | ± 0.3% | ±25°F | 180 | 140 | 100" | 300 | 4,500 lbs | |

| HD-243618-HT | 24" x 36" x 18" | 9 | 65" x 81" x 77" | 2,200°F | 48 | 450,000 | 11" | ± 0.3% | ±25°F | 165 | 125 | 100" | 360 | 4,800 lbs | |

| HD-243624-HT | 24" x 36" x 24" | 12 | 65" x 81" x 83" | 2,200°F | 56 | 520,000 | 11" | ± 0.3% | ±25°F | 155 | 120 | 110" | 360 | 5,700 lbs | |

| HD-244824-HT | 24" x 48" x 24" | 16 | 65" x 94" x 83" | 2,200°F | 65 | 600,000 | 11" | ± 0.3% | ±25°F | 150 | 130 | 110" | 480 | 6,500 lbs | |

| HD-304830-HT | 30" x 48" x 30" | 25 | 71" x 94" x 89" | 2,200°F | 72 | 700,000 | 11" | ± 0.3% | ±27°F | 165 | 130 | 118" | 600 | 7,300 lbs | |

| HD-306030-HT | 30" x 60" x 30" | 31.3 | 71" x 105" x 89" | 2,200°F | 78 | 725,000 | 11" | ± 0.3% | ±27°F | 180 | 140 | 118" | 700 | 8,400 lbs | |

| HD-364836-HT | 36" x 48" x 36" | 36 | 77" x 94" x 95" | 2,200°F | 78 | 800,000 | 11" | ± 0.3% | ±30°F | 180 | 140 | 135" | 750 | 8,600 lbs | |

| HD-366036-HT | 36" x 60" x 36" | 45 | 77" x 105" x 95" | 2,200°F | 88 | 850,000 | 11" | ± 0.3% | ±30°F | 180 | 150 | 135" | 850 | 9,800 lbs | |

| HD-367236-HT | 36" x 72" x 36" | 54 | 77" x 117" x 95" | 2,200°F | 100 | 1,000,000 | 11" | ± 0.3% | ±30°F | 180 | 150 | 135" | 1000 | 10,500 lbs | |

| HD-484836-HT | 48" x 48" x 36" | 48 | 89" x 94" x 95" | 2,200°F | 90 | 915,000 | 11" | ± 0.3% | ±30°F | 180 | 150 | 135" | 925 | 9,500 lbs | |

| HD-484848-HT | 48" x 48" x 48" | 64 | 89" x 94" x 107" | 2,200°F | 110 | 1,100,000 | 11" | ± 0.3% | ±33°F | 165 | 130 | 159" | 1100 | 10,500 lbs | |

| HD-487248-HT | 48" x 72" x 48" | 96 | 89" x 116" x 107" | 2,200°F | 158 | 1,500,000 | 11" | ± 0.3% | ±35°F | 140 | 120 | 159" | 1600 | 13,500 lbs | |

* Outside Dimensions

- All Models: Control panel overhang 9″ right side.

- Gas Models: Combustion blower overhang 36″ rear.

- Electric Models: Transformer overhang 24″ rear.

† Operating Characteristics

- Accuracy as percent of controller span.

- Uniformity at 100°F below maximum temperature.

- Rise Time in minutes to 100°F below maximum temperature.

- Tests run with empty oven and minimum exhaust.

- Performance will vary with load and application.

- See Control & Instrumentation Summary for additional details.

Specifications for High Temp Heavy Duty Box Furnace

| MODEL | HD-484848-HT |

|---|---|

| MAXIMUM OPERATING TEMP | 2,200°F |

| AIR FLOW | Radiant |

| CONTROL ACCURACY | ± 0.3% |

| OVEN UNIFORMITY | ±33°F |

| RISE TIME - ELECTRIC | 165 mins |

| RISE TIME - GAS | 130mins |

| WORKS SPACE DIMENSIONS (WxDxH) | 48" x 48" x 48" |

| SHELVES INCLUDED | None |

| NUMBER OF SHELVES MAX | None |

| SHELF CAPACITY | None |

| MAX LOAD CAPACITY | Not Available |

| DOORS | Air |

| LOADING METHOD | Floor |

| APPROXIMATE SHIP WEIGHT | 10500 lbs |

| OUTSIDE DIMENSIONS (WxDxH) | 89" x 94" x 107" |

Standard Features for High Temp Heavy Duty Box Furnace

Certifications

- UL Listed Control Panel

- Meets the Requirements of the Following Standards:

- NFPA 86 (Standard for Ovens and Furnaces)

- NFPA 70 (National Electric Code)

- FM (Factory Mutual)

- OSHA

- Caution:

- When processing combustible material fire protection should be considered

- Not for use with flammable solvents or vapors. Other models available for these applications. For more information see Class A Solvent Processing page at this website

Safety Equipment

- Adjustable manual reset excess temperature interlock to turn off heat on malfunction of main temperature controller

- Electric Heat Includes

- Separate heating element control contactors to turn off heat on malfunction of main control contactors

- Door interlock turns off power to heating elements when door is opened to protect operator from line voltage at heating elements

- Gas Heat Includes

- Multiple modulating burners fired under hearth from opposing sides to circulate heated air

- Automatic pre-ignition purge period to clear accumulated gas or fumes from furnace

- Push button electric ignition

- Microprocessor based electronic flame safeguard protection for each burner to continuously monitor flame and close gas valves if flame is not present

- Combustion air blower

- Combustion Blower air flow safety switch to close gas valves on loss of combustion air flow

- High and Low gas pressure switches to confirm safe operating pressure range

- Two pilot valves for each pilot to guarantee gas flow to pilot can be stopped

- Two main safety shut off valves for each burner with valve seat position indicator to assure gas flow to each main burner can be stopped

- Proof of closure switch on one main valve at each burner to prevent igniting pilot unless main valve is closed

- Leak test station at each pilot and main burner valve to allow testing for leakage through valve

- Door interlock drives main burners to low fire as door is opened to protect operator from flames

Controls

- Digital temperature controller

- SCR Power Controller

- LED pilot lights

- On-off heat switch

- 5 kA short circuit current rating (SCCR)

Construction

- Choice of

- Air or Inert Atmosphere construction

- Electric or Gas heat (Air construction only)

- 208 volt, 230 volt or 460 volt, 3-phase, 60 HZ – other input power available

- All welded construction

- High temperature Kanthal AF rod overbend heating elements beneath hearth and hanging from J-hooks on vertical walls

- Rear mounted power transformer provides low voltage for heating elements

- 1000 BTU per cubic foot natural gas at 2 psig pressure – propane available. Inlet 1” NPT up to 800,000 BTU/hr, 1-¼ “ NPT to 1,000,000 BTU/hr, 1-½” NPT above 1,000,000 BTU/hr

- Insulated with 4” of light weight, energy saving refractory ceramic fiber and 7” of firebrick (roof insulation 10” of Refractory Ceramic Fiber)

- Load supporting floor insulated with 4” of 18-½ lbs per cubic foot density 1900⁰F block and 7” of firebrick

- 3/16” steel plate reinforced furnace shell with Trilite Green enamel finish

- ½” thick steel front plate around door

- Fire brick throat and doorsill to protect furnace during loading

- Brushed stainless steel control panel face

- Powered vertical lift door

- Electric door: Electromechanical operator pivots door, supported by structural steel arms and bearings, upward above furnace

- Air door: Air cylinder lifts door hanging from heavy duty roller chain supported by sprockets, shaft and pillow block bearings

- Door hot side faces away from operator

- Soft insulation on door hot face seals against throat brick and steel front plate

- 2” thick , heavy duty ceramic hearth plates supported by fire brick piers

- Fully assembled and factory tested

- 1 year limited warranty

Modifications & Accessories for High Temp Heavy Duty Box Furnace

-

Alloy Hearth Tray

Furnace accessory adding a Alloy Hearth Tray – 253MA to 2000 F, 330 to 2200 F. Alloy protects ceramic hearth plates from impact and heavy loading.

-

Programmable Temperature Controller

Oven modification adding a programmable Temperature Controller. Microprocessor based, digital indicating, thermocouple actuated, in lieu of standard controller.

-Program Parameters: 40 profiles of up to 50 steps each, a real-time clock with battery backup to allow starting profile at any time of day

-Digital Display, 4.3” color touch screen

-Accuracy, ±0.1% of span plus 1 degree display error

-Connectivity, Relay output for alarm or other notification, two (2) USB ports, Ethernet compatible

Also Available:

-Up to four (4) control channels of temperature, relative humidity or vacuum

-Monitor up to16 sensors

-Math and logic functions

-Digital inputs and outputs

-Data logging

-Graphic Trending

-

Recording Thermometer

Accessory adding a Recording Thermometer. Thermocouple actuated.

- Record: 10″ diameter circular chart 24 hour chart rotation

- Digital Display: 0.56″ high, LED, alphanumeric, 4 digit display; LED status display

- Accuracy: ±0.25%of span plus 1 degree display error

-

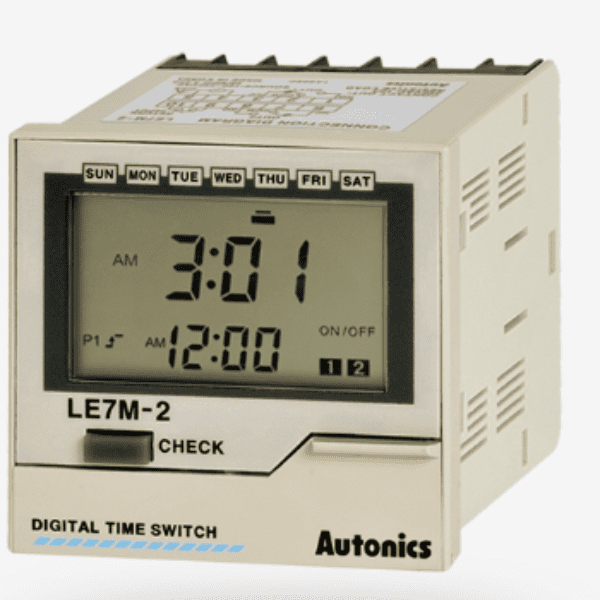

Digital Shut Down Timer

Accessory adding a Digital Shut Down Timer. Shuts down oven, selectable range, continuous “hold” feature.

-

Install Customer Supplied Temperature Controller

Modification installing a customer supplied temperature controller in lieu of standard controller.

-

Digital Batch Timer

Oven modification adding a Digital Batch Timer. Uniformly timing batch operations, continuous alarm with door interlock, alarm sounds at end of preset time until door is opened or timer reset.

-

Supply Oven Without Controller

Supply without temperature controller. Supply cutout, thermocouple, and wires only. Customer to supply and install temperature controller.

-

Program Timer

Oven modification adding a programmable 24 hour, 7 day timer.

-

Equipment Shut Down Via Event Output

Modification adding a Equipment Shut Down Via Event Output. Shuts down oven via event output on programmable controller.

Custom Furnaces

-

Model HD-244824-ATM Inert Atmosphere High Temperature Furnace

Serial #: 700036Brick interior with rod overbend heaters

- MAX TEMP: 2200ºF

- WORKSPACE DIMS (WxDxH): 24" x 48" x 24"