FAQs

Here are some of our most commonly asked questions when it comes to buying, owning, and maintaining an industrial heat treat oven or furnace.

Here are some of our most commonly asked questions when it comes to buying, owning, and maintaining an industrial heat treat oven or furnace.

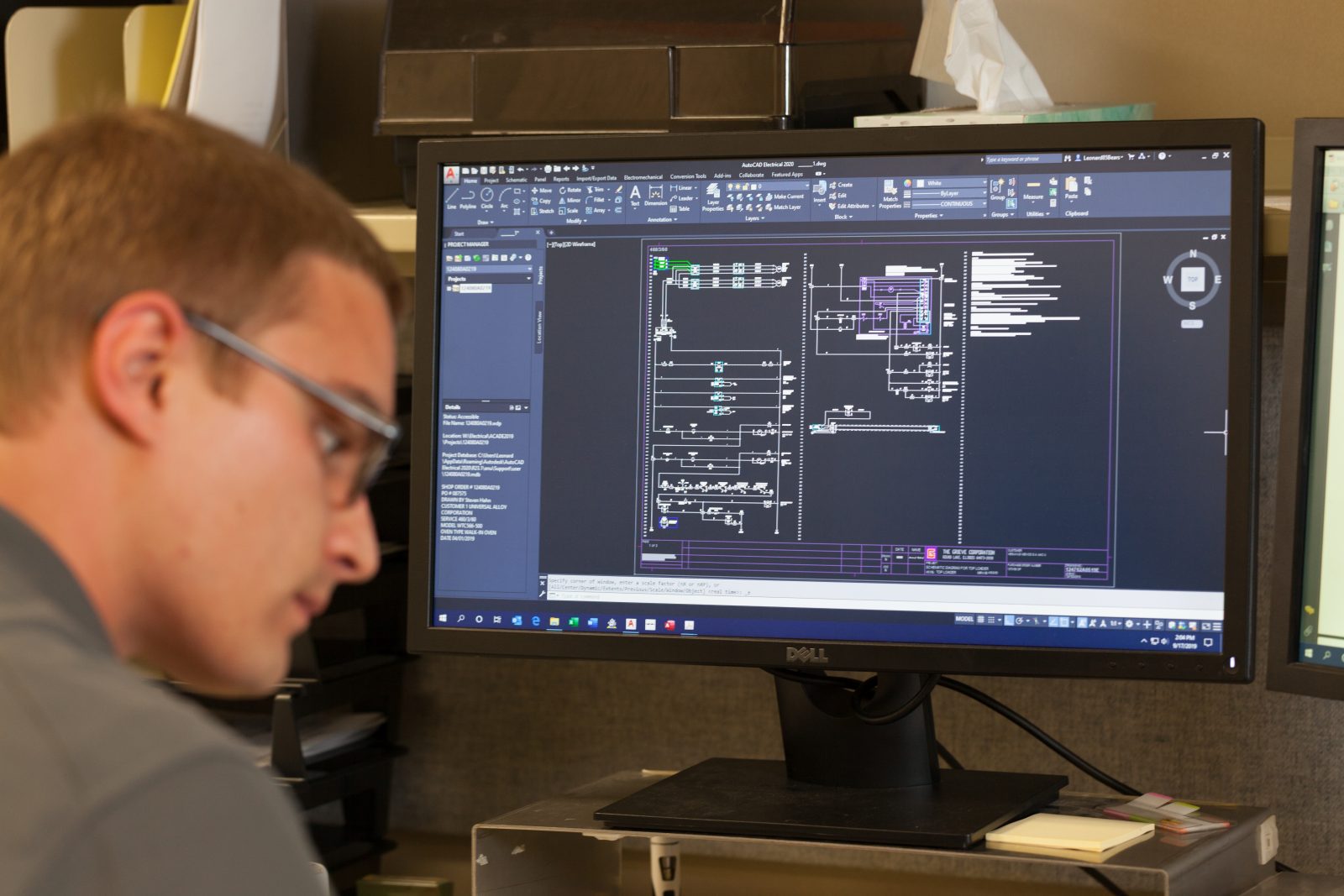

Manuals and electrical wiring diagrams are made individually for each piece of equipment with the exception of the Laboratory Ovens. A copy of the electrical wiring diagram is included in the operating manual and a second copy is bolted to the inside of the control panel door. Replacement operating manuals and wiring diagrams can be purchased here. The equipment serial number will be required when placing an order.

Please follow this link for our General Operating Instructions. General Operating Instructions for Laboratory Ovens include an electrical wiring diagram. All other electrical wiring diagrams are made individually for each oven.

Refer to our Resource Library which contains component manuals with information on error code displays and troubleshooting.

Typically our equipment can be serviced by your maintenance department. If additional help is required our technical support department can provide further assistance over the phone. As an alternative you can contact your local Grieve area sales representative who will put you in touch with a local mechanical service group.

(Even though the heating elements or burner are not on, any equipment with recirculating blower will heat up to about 30°F above room temperature due to the energy added by the blower.)

For Electrically Heated Equipment:

For Gas-Fired Equipment:

The decision whether to stock replacement parts is based on how critical the equipment operation is to production. If equipment is critical and a few days to a week of down time would not be acceptable, we would suggest stocking heating elements, heating element contactors, thermocouple, blower and exhauster (if equipped) motors, V-belts (if equipped), door gasket, fuses, bearings (if equipped), latches and hinges. Most parts are available from our stock. Some parts such as non-standard temperature controllers, SCR power controllers, entire gas burners and special blower wheels are not stocked and availability is based on our vendor’s delivery. Some of these parts could have long delivery, but also may be able to be repaired by our vendor.

Some voltage supply variance is acceptable. For example, equipment built to function on 460V will work on 440 as well as 480 volts. Changing the phase (1-phase or 3-phase), frequency (50 Hz or 60 Hz), or a large change in voltage (between 208 volts, 230 volts, 380 volts, 460 volts, 600 volts) will require equipment retrofit kits. Not all changes will be economically feasible. Please locate the serial number of your equipment and contact our sales team or contact your local representative for further assistance and a quotation.

The ovens are expected to run under a slight positive pressure. It is expected that the area immediately around the doors and at truck track seals will run hotter than the rest of the oven walls. There should be minimal heat leaking around the doors unless the door gaskets have deteriorated or the doors are damaged.

Door seal can be checked by closing a piece of paper between the gasket and oven face to make sure the gasket is touching the face of the oven. There should be resistance to pulling out the paper all around the perimeter of the doors. Doors can be adjusted at the hinges or by adjusting catch standoffs. Check to make sure that the oven is level and on a firm floor. To some extent the oven will form fit to the floor resulting in a warped oven face that is hard to seal to. If the top corners at the gap between double doors do not line up, the oven is not level. The oven should be shimmed to correct this.

Operating an oven under negative pressure will cause colds spots where room air is pulled in around the door seals. Oven negative pressure can be caused by the room where the oven is located being under negative pressure. This results in the room pulling air down the oven exhaust stack, through the oven and hot air into the room.

Internal oven pressure can be adjusted by setting of the fresh air inlet and exhaust outlet. Increasing fresh air into the oven by opening the fresh air inlet will increase pressure in the oven. Increasing exhaust by opening the exhaust outlet will decrease pressure in the oven.

Please contact our sales team or contact your local representative for further assistance.

If after taking these steps, uniformity is still in question please contact our tech support for further steps

Contactor with something caught in the coil or failing contacts can cause “chattering”. If this is the case, the contactor should be cleaned out or replaced.

Do not change processing in existing equipment without determining whether the new process includes flammable solvents or gives off flammable vapors. If existing process includes flammable solvents or vapors, make sure the new process does not include a greater amount of flammable solvent or produce more flammable vapors. If oven does not include correctly sized Class A equipment or the equipment is not sized correctly an explosion and fire could result causing damage to property and injury or death to employees.

Our sales team will be happy to review the feasibility of your new process taking place in existing equipment. They will review all key aspects and provide a solution or recalibration of your existing equipment. Please locate the serial number of your equipment and contact our sales team or contact your local representative to discuss your application.

OSHA requires ovens processing flammable solvents or vapors to conform to the National Fire Protection Association Standard 86. NFPA 86 defines ovens for these applications as Class A ovens.

In order to keep flammable vapor concentration at safe levels, Class A ovens include additional equipment to provide safety ventilation. This additional equipment is sized based on the volume of solvent being evaporated and the maximum operating temperature. Feel free to reach out to Grieve directly for any specific questions related to Class A ovens or questions regarding required exhauster size and heat loss at (847) 546-8225 or contact us.

Read more about Class A equipment for solvent processing here.

OSHA requires ovens processing flammable solvents or vapors to conform to the National Fire Protection Association Standard 86. NFPA 86 defines ovens for these applications as Class A ovens.

In order to keep flammable vapor concentration at safe levels, Class A ovens include additional equipment to provide safety ventilation. This additional equipment is sized based on the volume of solvent being evaporated and the maximum operating temperature. Feel free to reach out to Grieve directly for any specific questions related to Class A ovens or questions regarding required exhauster size and heat loss at (847) 546-8225 or contact us.

Read more about Class A equipment for solvent processing here.

If your operating temperature is above 1250F Grieve will be providing a furnace solution. If you’re operating temperature is 1250F or below we will provide an oven solution.

The Grieve Corporation, an OEM manufacturer of Industrial Oven & Industrial Furnaces, does not buy and resell used equipment. However, we are aware that there is a large market in used industrial ovens and industrial furnaces.

We are often contacted, after a used oven or used furnace has been purchased, to help the new owner get the unit up and running. For this reason, we are very aware of the pitfalls of purchasing used industrial equipment. Before purchasing a used industrial oven or a used industrial furnace, reference the following link: New versus Used equipment

Our ovens and furnaces can be equipped and tested to comply with AMS 2750. The “Furnace Class” and “Instrumentation Type” must be provided in order for us to quote correct equipment with proper instrumentation.

We have a handy oven finder tool that can help you narrow down a type of oven based on the various temperatures and specifications for your worksite. Once you find the oven you think may work, add it to the quote cart, and submit the form to request more information. This will start the conversation with our consultation team. browsE ovens

Clicking a link below will navigate you to a page with detailed instructions for the calculations.

Annealing is a process that is used to change hardness and strength of a product, typically made from metal. Annealing makes a product easier to work with by reducing the hardness. It is typical for an annealing furnace to have an inert atmosphere to protect product from discoloration.

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid.

Curing is a chemical process employed in polymer chemistry and process engineering that produces the toughening or hardening of a polymer material by cross-linking of polymer chains.

Heat treating is a process used to alter the physical, and sometimes chemical, properties of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching.

Stress relief reduces the internal material stresses within a part or welded assembly caused by manufacturing processes like forming, machining, cutting or welding. By heating the component or assembly and holding for sufficient time the internal stress can be reduced.

OSHA requires ovens processing flammable solvents or vapors to conform to the National Fire Protection Association Standard 86. NFPA 86 defines ovens for these applications as Class A ovens.

In order to keep flammable vapor concentration at safe levels, Class A ovens include additional equipment to provide safety ventilation. This additional equipment is sized based on the volume of solvent being evaporated and the maximum operating temperature. Feel free to reach out to Grieve directly for any specific questions related to Class A ovens or questions regarding required exhauster size and heat loss at (847) 546-8225 or contact us.

Read more about Class A equipment for solvent processing here.

AMS 2750 is a heat treatment standard predominantly used in the aerospace industry. It covers temperature sensors, instrumentation, thermal processing equipment, system accuracy tests, and temperature uniformity surveys. These are necessary to ensure that parts or raw materials are heat treated in accordance with design requirements. The AMS 2750 specification has specific requirements for recording, calibration of controlling thermocouple, location of fixed permanent reference thermocouples and temperature uniformity testing. There are different requirements on recording and temperature uniformity depending on the use of the equipment being tested.

Inert atmosphere is used to minimize oxygen contacting parts during heating. The most common use of inert atmosphere is to avoid discoloration or scaling of parts that would occur if heated in presence of oxygen. There are other processes that require inert atmosphere during heating due to the specific nature of the product being treated.

Passes heated air across each shelf level. Use when processing flat sheets or parts with the least restriction to airflow from left to right within workspace.

Use when processing flat sheets or parts with the least restriction to airflow from front to rear within workspace. Accommodates virtually any oven loading without restricting air passage

For workloads where the heated air must pass upward through the load. Use when processing parts with the least restriction to airflow vertically within workspace.

Radiation heat transfer occurs via electromagnetic waves. It is best used for applications above 1400°F.

Convection heat transfer in ovens involves bulk flow of air from a hotter region to a colder one. Gravity convection takes advantage of the natural rise of heated air to minimize air movement disturbance within the oven work space.

Convection heat transfer in ovens involves bulk flow of air from a hotter region to a colder one. Forced convection uses a blower to accelerate heat transfer and improve temperature uniformity.