Tunnel Ovens

Tunnel Ovens

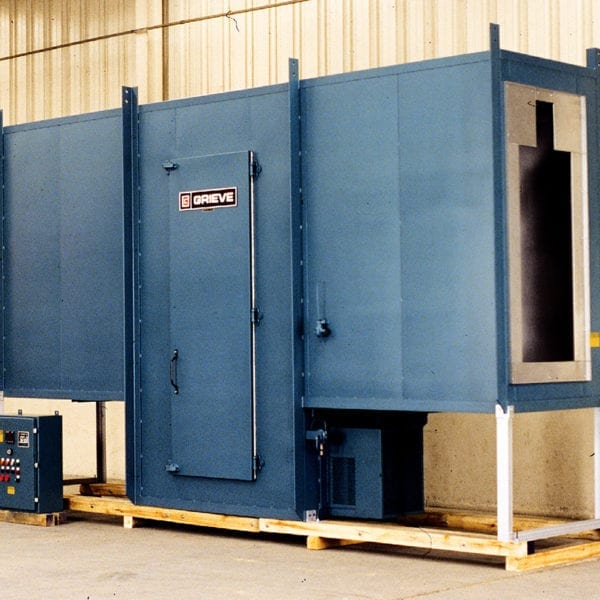

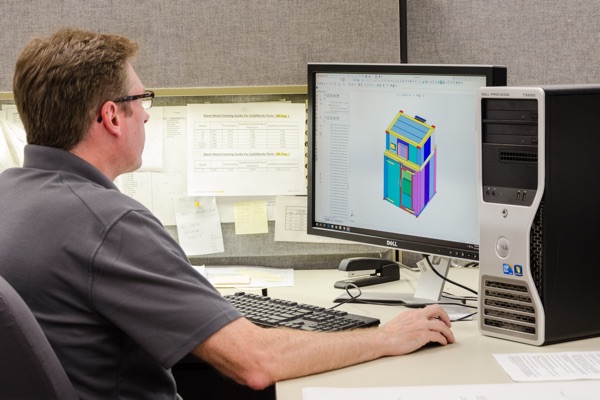

Tunnel ovens are designed for use with the customer’s conveyor system. Our experienced engineers will collect the features of your conveyor system and develop a tunnel oven to support your conveyor as well as meet your particular heat processing requirements. Units can be provided in sections for easy installation and mating with existing conveyor system.

Standard Features for Tunnel Ovens

Certifications

- UL Listed Control Panel

- Meets the Requirements of the Following Standards:

- NFPA 86 (Standard for Ovens and Furnaces)

- NFPA 70 (National Electric Code)

- FM (Factory Mutual)

- OS

Caution:

-

- Ovens processing combustible materials are required to have a fire suppression system per NFPA 86

- If flammable solvents or vapors are present in an oven, OSHA requires conformance with NFPA 86 Class A Oven requirements. A powered forced exhauster and other non-standard safety equipment must be added. See Class A Oven Equipment for Solvent Processing resource page for more information.

Safety Equipment

- Adjustable manual reset excess temperature interlock to turn off heat on malfunction of main temperature controller

- Recirculating blower air flow safety switch to turn off heat on loss of recirculated air flow

- Electrical interlock shuts off heat if power to recirculating blower is interrupted

- Electric Heat Includes

- Separate heating element control contactors to turn off heat on malfunction of main control contactors

- Gas heat includes:

-

- Modulating burner for 1000 BTU per cubic foot natural gas at 6” water column pressure – propane available.

- Automatic pre-ignition purge period to clear accumulated gas or fumes

- Push button electric ignition

- Microprocessor based electronic flame safeguard protection to continuously monitor flame and close gas valves if flame is not present

- Powered forced exhauster to provide combustion venting

- Exhauster air flow safety switch to close gas valves on loss of venting

- Two pilot valves to guarantee gas flow to pilot can be stopped

- High and Low gas pressure switches to confirm safe operating pressure range

- Two main burner safety shut off valves with valve seat position indicator to assure gas flow to main burner can be stopped

- Proof of closure switch on one main valve to prevent igniting pilot unless main valve is closed

- Leak test station at each pilot and main burner valve to allow testing for leakage through valve

Controls:

- Digital temperature controller

- Motor control push buttons and on-off heat switch

- LED pilot lights

- 5 kA short circuit current rating (SCCR)

Construction:

Available construction features:

Oven design can include:

- multiple heat zones

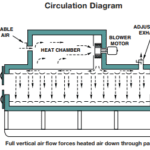

- vertical or horizontal recirculated air flow

- cooling zone to reduce part temperature before handling

- unheated vestibules to reduce heat loss from ends of oven

- support points for existing conveyor system

- slide beds for conveyor belts

- tracks for monorail conveyors

- vertical lift doors tied to indexing

Conveyor support can be designed to accommodate all conveyor types including:

- flat wire belts

- woven wire belts

- cross bar

- multi-strand roller chain

- monorails

- power or free roller conveyor

Choice of:

-

- Maximum operating temperatures up to 1200°F

- Vertical or horizontal recirculated air flow

- Aluminized steel or stainless steel interior

- Electric or Gas heat

- 208 volt, 230 volt or 460 volt, 3-phase, 60 HZ – other input power available

- Design can include:

- Multiple heat zones

- Extended loading and unloading zones to accumulate parts

- Wire, cross bar, roller chain, and other belt options available

- Special belt construction or attachments

- Support points for existing conveyor system

- Slide beds for conveyor belts

- Tracks for monorail conveyors

- Cooling zone to reduce part temperature before handling

- Unheated vestibules to reduce heat loss from ends of oven

- Vertical lift doors tied to indexing

- All welded construction

- Structural steel base provides rigid assembly easily moved into position

- Conveyor supports held by cross angles welded to vertical wall members to transfer belt load to factory floor

- Heavy duty reducer, torque limiting device and variable frequency conveyor drive

- Durable, electrically isolated, Incoloy tubular heating elements

- Heat source located in heat chamber to prevent radiant heating

- High pressure recirculating blower

- Full coverage supply and return duct work with adjustable opposed louvers

- Adjustable fresh air intake and exhaust outlet damper

- Insulated with 10 lbs per cubic foot density rockwool insulation

- Aluminized steel exterior with Trilite Green enamel finish

- Includes 2” refractory ceramic fiber insulation on 16 gauge aluminized steel interior walls, 16 gauge 304 stainless steel heat chamber walls and stainless steel recirculating blower

- Brushed stainless steel control panel face

- Heavy duty access doors along oven length with explosion venting latches

- Adjustable dampers at ends of heat zone positioned near load to reduce heat loss

- Slip flashing at doorways allow inner oven to expand without affecting door sealing

- Fiberglass door gasket with stainless steel spring insert

- Fully assembled and factory tested for temperature uniformity

- 1 year limited warranty

Modifications & Accessories for Tunnel Ovens

-

Programmable Temperature Controller

Oven modification adding a programmable Temperature Controller. Microprocessor based, digital indicating, thermocouple actuated, in lieu of standard controller.

-Program Parameters: 40 profiles of up to 50 steps each, a real-time clock with battery backup to allow starting profile at any time of day

-Digital Display, 4.3” color touch screen

-Accuracy, ±0.1% of span plus 1 degree display error

-Connectivity, Relay output for alarm or other notification, two (2) USB ports, Ethernet compatible

Also Available:

-Up to four (4) control channels of temperature, relative humidity or vacuum

-Monitor up to16 sensors

-Math and logic functions

-Digital inputs and outputs

-Data logging

-Graphic Trending

-

Digital Timing Temperature Controller

Modification adding a Digital Timing Temperature Controller. Microprocessor based, incorporates 99 hour 59 minute timer, starts timing temperature reaches set point and shuts down oven at end of set time.

- Digital Display, two LED, alphanumeric, 4 digit displays; 0.875″ high for temperature display and 0.500″ high for set point display

- Accuracy, ±0.1% of span plus 1 degree display error

-

Recording Thermometer

Accessory adding a Recording Thermometer. Thermocouple actuated.

- Record: 10″ diameter circular chart 24 hour chart rotation

- Digital Display: 0.56″ high, LED, alphanumeric, 4 digit display; LED status display

- Accuracy: ±0.25%of span plus 1 degree display error

-

SCR Power Controller

Electrical modification adding an SCR Power Controller. Features:

•Silicon controlled rectifier power controllers are completely solid state industrial controllers that ensure precise proportioning of electric power to the heating elements.

•Oven temperature is maintained smoothly and evenly over the entire temperature range of the unit.

•SCR power controllers minimize maintenance, as there are no moving parts or electrical contacts to wear out.

•Heating element fatigue is reduced since the elements do not cool between releases of electric power.

•Zero voltage firing, including the first one half cycle of voltage, minimizes radio frequency and electromagnetic interference.

•Transient voltage suppressor networks are included, and the units are provided with protective fusing.

-

Digital Shut Down Timer

Accessory adding a Digital Shut Down Timer. Shuts down oven, selectable range, continuous “hold” feature.

-

Install Customer Supplied Temperature Controller

Modification installing a customer supplied temperature controller in lieu of standard controller.

-

Digital Batch Timer

Oven modification adding a Digital Batch Timer. Uniformly timing batch operations, continuous alarm with door interlock, alarm sounds at end of preset time until door is opened or timer reset.

-

Supply Oven Without Controller

Supply without temperature controller. Supply cutout, thermocouple, and wires only. Customer to supply and install temperature controller.

-

Program Timer

Oven modification adding a programmable 24 hour, 7 day timer.

Custom Ovens

-

Gas-Heated Tunnel Oven

Serial #: 660436Hung from ceiling includes interior supports for customer’s monorail and, remote control panel.

- MAX TEMP: 350ºF

- WORKSPACE DIMS (WxDxH): 30" x 192" x 66"

-

Special Gas-Heated Walk-In Oven

Serial #: 6604432′ x 24′ x 4′ five monorail tracks mounted at top of work space for curing carbon/epoxy components hung on monorails

- MAX TEMP: 350ºF

- WORKSPACE DIMS (WxDxH): 36" x 282" x 48"

-

Electrically-Heated Walk-In Oven

Serial #: 4119513′ x 25′ x 3′ designed for heat treating long fluorocarbon shapes on wheeled supports

- MAX TEMP: 500ºF

- WORKSPACE DIMS (WxDxH): 36" x 300" x 36"

-

Tunnel Oven with Gravity Roller Conveyor

Serial #: 85163A10055-1/2′ wide roller conveyor includes NEMA 12 dust tight, oil tight electrical construction

- MAX TEMP: 350ºF

- WORKSPACE DIMS (WxDxH): 66" x 228" x 15"

-

Tunnel Oven with Gravity Roller Conveyor

Serial #: 88008C0706Tunnel oven with roller conveyor and vertical lift doors on each end

- MAX TEMP: 500ºF

- WORKSPACE DIMS (WxDxH): 42" x 72" x 30"