Inert Atmosphere Bench Furnace

Inert Atmosphere Bench Furnace

These furnaces are specifically designed for heat treating applications requiring inert atmosphere protection. Inert atmospheres protect the work from oxidation. Precision microprocessor based temperature controls and energy-saving insulation maximize the cost efficiency and performance of these rugged units. Ideal for heat treating of tools, dies and other parts.

Inert Atmosphere Bench Furnace Model Specifications:

Not for use with flammable solvents, vapors, or gases.

| Model | Workspace | Outside Dimensions*(WxDxH) | Max Temp | Heat Input | Insulation Thickness | Operating Characteristics† | Door Type | Height w/ Door Open | Hearth Rating | Approx Shipping Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions(WxDxH) | VolumeCu Ft | ElectricKW | GasBTU/HR | Control Accuracy | Temperature Uniformity | Rise Time (Electric) | Rise Time (Gas) | ||||||||

| BAF-8128 | 8" x 12" x 8" | 0.4 | 24" x 31" x 31" | 2,000°F | 4.5 | Not Available | 5" | ± 0.3% | ±15°F | 65 | Not Available | 52" | 60 | 420 lbs | |

| BAF-8128-HT | 8" x 12" x 8" | 0.4 | 26" x 33" x 33" | 2,200°F | 4.5 | Not Available | 6" | ± 0.3% | ±20°F | 75 | Not Available | 54" | 60 | 505 lbs | |

| BAF-12128 | 12" x 12" x 8" | 0.7 | 28" x 31" x 31" | 2,000°F | 6 | Not Available | 5" | ± 0.3% | ±15°F | 55 | Not Available | 52" | 60 | 470 lbs | |

| BAF-12128-HT | 12" x 12" x 8" | 0.7 | 30" x 33" x 33" | 2,200°F | 6 | Not Available | 6" | ± 0.3% | ±20°F | 80 | Not Available | 54" | 60 | 550 lbs | |

| BAF-121212 | 12" x 12" x 12" | 1 | 28" x 31" x 37" | 2,000°F | 7.5 | Not Available | 5" | ± 0.3% | ±12°F | 50 | Not Available | 66" | 60 | 520 lbs | |

| BAF-121212-HT | 12" x 12" x 12" | 1 | 30" x 33" x 39" | 2,200°F | 7.5 | Not Available | 6" | ± 0.3% | ±17°F | 65 | Not Available | 68" | 60 | 620 lbs | |

| BAF-12188 | 12" x 18" x 8" | 1 | 28" x 37" x 31" | 2,000°F | 7.5 | Not Available | 5" | ± 0.3% | ±10°F | 65 | Not Available | 52" | 60 | 545 lbs | |

| BAF-12188-HT | 12" x 18" x 8" | 1 | 30" x 39" x 33" | 2,200°F | 7.5 | Not Available | 6" | ± 0.3% | ±15°F | 75 | Not Available | 54" | 60 | 645 lbs | |

| BAF-121812 | 12" x 18" x 12" | 1.5 | 28" x 37" x 37" | 2,000°F | 12 | Not Available | 5" | ± 0.3% | ±10°F | 45 | Not Available | 66" | 60 | 570 lbs | |

| BAF-121812-HT | 12" x 18" x 12" | 1.5 | 30" x 39" x 39" | 2,200°F | 12 | Not Available | 6" | ± 0.3% | ±15°F | 60 | Not Available | 68" | 60 | 675 lbs | |

| BAF-12248 | 12" x 24" x 8" | 1.3 | 28" x 43" x 31" | 2,000°F | 12 | Not Available | 5" | ± 0.3% | ±10°F | 50 | Not Available | 52" | 60 | 680 lbs | |

| BAF-12248-HT | 12" x 24" x 8" | 1.3 | 30" x 45" x 33" | 2,200°F | 12 | Not Available | 6" | ± 0.3% | ±15°F | 60 | Not Available | 54" | 60 | 755 lbs | |

| BAF-122412 | 12" x 24" x 12" | 2 | 28" x 43" x 37" | 2,000°F | 15 | Not Available | 5" | ± 0.3% | ±10°F | 45 | Not Available | 66" | 60 | 775 lbs | |

| BAF-122412-HT | 12" x 24" x 12" | 2 | 30" x 45" x 39" | 2,200°F | 15 | Not Available | 6" | ± 0.3% | ±15°F | 60 | Not Available | 68" | 60 | 850 lbs | |

† Operating Characteristics

- Accuracy as percent of controller span.

- Uniformity at 100°F below maximum temperature.

- Rise Time in minutes to 100°F below maximum temperature.

- Tests run with empty oven and minimum exhaust.

- Performance will vary with load and application.

- See Control & Instrumentation Summary for additional details.

Heat Input footnote:

Electric KW shown above in specification chart is illustrated with 230V. For 460V, reference the below:

- BAF-8128 & BAF-8128-HT: 6 kW

- BAF-12128 & BAF-12128-HT: 8 kW

- BAF-121212 & BAF-121212-HT: 10 kW

- BAF-12188 & BAF-12188-HT: 10 kW

- BAF-121812 & BAF-121812-HT: 16 kW

- BAF-12248 & BAF-12248-HT: 16 kW

- BAF-122412 & BAF-122412-HT: 20 kW

Specifications for Inert Atmosphere Bench Furnace

| MODEL | BAF-12248-HT |

|---|---|

| MAXIMUM OPERATING TEMP | 2,200°F |

| AIR FLOW | Radiant |

| CONTROL ACCURACY | ± 0.3% |

| OVEN UNIFORMITY | ±15°F |

| RISE TIME - ELECTRIC | 60 mins |

| RISE TIME - GAS | Not Rated |

| WORKS SPACE DIMENSIONS (WxDxH) | 12" x 24" x 8" |

| SHELVES INCLUDED | None |

| NUMBER OF SHELVES MAX | None |

| SHELF CAPACITY | None |

| MAX LOAD CAPACITY | Not Available |

| DOORS | Manual |

| LOADING METHOD | Floor |

| APPROXIMATE SHIP WEIGHT | 755 lbs |

| OUTSIDE DIMENSIONS (WxDxH) | 30" x 45" x 33" |

Standard Features for Inert Atmosphere Bench Furnace

Certifications

- UL Listed Control Panel

- Meets the Requirements of the Following Standards:

- NFPA 86 (Standard for Ovens and Furnaces)

- NFPA 70 (National Electric Code)

- FM (Factory Mutual)

- OSHA

- Caution:

- For use with inert atmospheres only cannot be used with flammable gases

- When processing combustible material fire protection should be considered

- Not for use with flammable solvents or vapors. Other models available for these applications. For more information see Class A Solvent Processing page at this website

Safety Equipment

- Adjustable manual reset excess temperature interlock to turn off heat on malfunction of main temperature controller

- Separate heating element control contactors to turn off heat on malfunction of main control contactors

- Door interlock turns off power to heating elements when door is opened to protect operator from line voltage at heating elements

Controls

- Digital temperature controller

- LED pilot light

- On-off heat switch

- 5 kA short circuit current rating (SCCR)

Construction

- 208 volt (at 80% of 230 volt heat input), 230 volt or 460 volt, 3-phase, 60 HZ – other input power available

- Heavy gauge continuously welded construction to maintain atmosphere purity

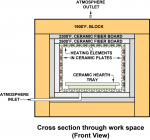

- Stainless steel atmosphere inlet (1/2” NPT at left side) and outlet (3/4” NPT at top rear)

- High temperature Kanthal A-1 coiled wire heating elements supported in rugged ceramic plates (Note: when operating above 1950⁰F furnace must be periodically run with air atmosphere to maintain protective oxide coating on heating elements)

- Heating elements located on sidewalls and ceiling of work space for excellent temperature uniformity

- Sealed heater terminal box at rear of furnace to prevent air from entering

- Heater terminal box vent cock to allow purging of air from heater terminal box

- Insulated with light weight, energy saving refractory ceramic fiber

- Heavy gauge aluminized steel exterior with Trilite Green enamel finish

- Brushed stainless steel control panel face

- Gas spring assisted manually operated vertical lift door

- Door hot side faces away from operator

- High temperature, refractory ceramic fiber, door gasket to contain atmosphere

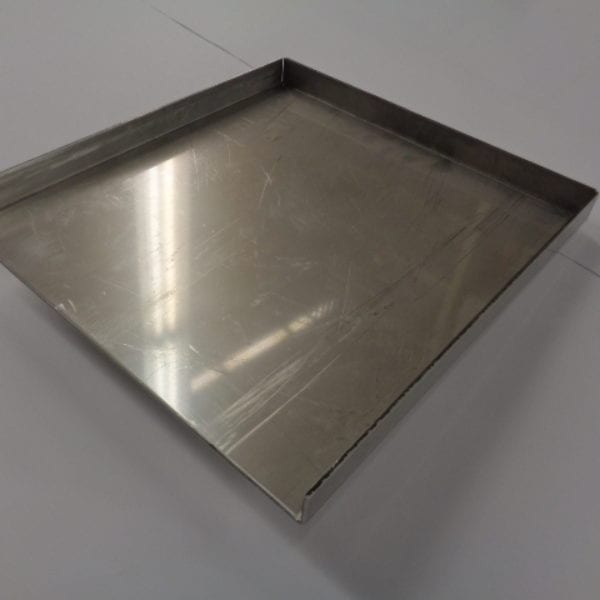

- Removable ceramic hearth tray

- Fully assembled and factory tested

- 1 year limited warranty

Modifications & Accessories for Inert Atmosphere Bench Furnace

-

Floor Stand

Furnace accessory adding a 26″ high floor stand steel cabinet with shelf.

-

Alloy Hearth Tray

Furnace accessory adding an Alloy Hearth Tray. Manufactured with heat resistant alloy that protects ceramic hearth plates from impact and heavy loading.

-

Programmable Temperature Controller

Oven modification adding a programmable Temperature Controller. Microprocessor based, digital indicating, thermocouple actuated, in lieu of standard controller.

-Program Parameters: 40 profiles of up to 50 steps each, a real-time clock with battery backup to allow starting profile at any time of day

-Digital Display, 4.3” color touch screen

-Accuracy, ±0.1% of span plus 1 degree display error

-Connectivity, Relay output for alarm or other notification, two (2) USB ports, Ethernet compatible

Also Available:

-Up to four (4) control channels of temperature, relative humidity or vacuum

-Monitor up to16 sensors

-Math and logic functions

-Digital inputs and outputs

-Data logging

-Graphic Trending

-

Digital Timing Temperature Controller

Modification adding a Digital Timing Temperature Controller. Microprocessor based, incorporates 99 hour 59 minute timer, starts timing temperature reaches set point and shuts down oven at end of set time.

- Digital Display, two LED, alphanumeric, 4 digit displays; 0.875″ high for temperature display and 0.500″ high for set point display

- Accuracy, ±0.1% of span plus 1 degree display error

-

SCR Power Controller

Electrical modification adding an SCR Power Controller. Features:

•Silicon controlled rectifier power controllers are completely solid state industrial controllers that ensure precise proportioning of electric power to the heating elements.

•Oven temperature is maintained smoothly and evenly over the entire temperature range of the unit.

•SCR power controllers minimize maintenance, as there are no moving parts or electrical contacts to wear out.

•Heating element fatigue is reduced since the elements do not cool between releases of electric power.

•Zero voltage firing, including the first one half cycle of voltage, minimizes radio frequency and electromagnetic interference.

•Transient voltage suppressor networks are included, and the units are provided with protective fusing.

-

Recording Thermometer

Accessory adding a Recording Thermometer. Thermocouple actuated, includes floor stand. Recorder cannot fit in standard control panel so floor stand must be included to accommodate recorder.

-Record: 10″ diameter circular chart 24 hour chart rotation

-Digital Display: 0.56″ high, LED, alphanumeric, 4 digit display; LED status display

-Accuracy: ±0.25%of span plus 1 degree display error

-

Digital Shut Down Timer

Accessory adding a Digital Shut Down Timer. Shuts down oven, selectable range, continuous “hold” feature.

-

Install Customer Supplied Temperature Controller

Modification installing a customer supplied temperature controller in lieu of standard controller.

-

Digital Batch Timer

Oven modification adding a Digital Batch Timer. Uniformly timing batch operations, continuous alarm with door interlock, alarm sounds at end of preset time until door is opened or timer reset.