Our end-to-end process is designed to build you an oven or furnace that endures.

When one of our ovens goes out the door, it’s been tested. It’s been vetted. From complete paint coverage to gasket fit, door hinge alignment, wire bundling neatness, shelf and accessory item counting, every aspect of a Grieve oven or furnace is carefully checked by a member of our company’s management before the unit is crated for shipment.

Our ovens are strong, hot, and as powerful as desired for your heat processing needs, the first time you turn it on and every time after. They’re built to last.

“I have purchased more than 20 ovens over the years and will only purchase Grieve now because of their excellent quality and customer service.”

Excellence never ends. Our process ensures your oven works from the first time you fire it up.

Consultation

Our sales team is pretty unique: they know the ovens as well as our engineers. Heck, most of them are engineers. They understand your industry, understand your needs, and understand how to find the right product for you. Designing your oven begins well before any contract is signed.

“Helping you get an oven that will last 50 years is my only metric for success.”

—Dale Message, Senior Applications Engineer, Grieve

IndustriaL Oven Manufacturing

Our team is experienced. We understand what it takes to transform a design into a real oven that will be worked on by generations of your employees. We know your work is important. Our dedicated team is thorough, collaborative, and tireless. Honestly, we just love manufacturing industrial ovens. We’re ready for it to come to the floor.

“There’s nothing more exciting than getting a design and making it your reality.”

—Tom Conticello, Plant Manager, Grieve

Did you know?

Testing

The testing of a Grieve oven or furnace is done with the same care and attention to detail as the design and manufacturing stages. We test everything you might see in the field. If we didn’t, you’d be doing our testing for us. That’s not the way we do things at Grieve. No Grieve product gets its nameplate until it passes our rigorous test procedure. Our family name is on the door…anything less than the best won’t do.

“It has to work on our floor so we know it will work on yours. You shouldn’t have to worry about anything past preventative maintenance.”

—James McGee, Lead Tester, Grieve

Inspection

Every Grieve manufactured oven or furnace is fully performance tested. Now, our finishers take over to complete the last few steps in the manufacture of a Grieve product. Over 100 aspects of a Grieve product are carefully checked by a member of our company’s management before a unit is crated for shipment.

“Every job is a self-portrait of the person who did it. We autograph our work with excellence!”

—Justin Payne, Foreman & Quality Control, Grieve

Shipping Logistics

Some ovens are huge. Some need to go overseas. Some need to fit under bridges. When we ship you your oven, we take everything into account, making sure that anything that needs to be disassembled will be easily assembled. Our motto is to not leave anything to chance. When your oven gets to you, it is safe, secure, and ready to be assembled.

“Large rivers? Tiny doors? Have to get across a pristine campus? We’ve done it all- and we’ll make it happen for you.”

—Gayle Teltz, Shipping Manager, Grieve

Startup & Training

Your oven has to work the first time. If needed, our team will help you assemble, install, and get fired up. There is no detail too small not to be done right, and getting your oven set up is a pledge we take seriously. We want you to start the next few decades of use as soon as possible. We’re with you every step of the way.

“It’s great to see our oven set up on your floor. I’m proud to help make that happen.”

—Randy Bono, Field Technician, Grieve

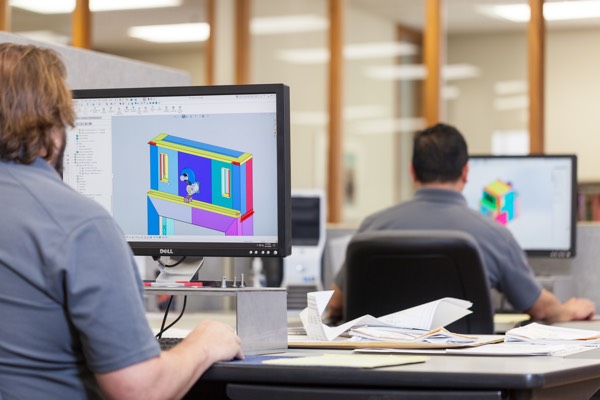

Oven Design

Grieve quality begins with the engineer’s very first layout. The highly sophisticated CAD equipment shown here translates thoughts into form, form into function. We make sure that your industrial oven is designed to your unique, often customized design specifications, and that it can be built perfectly.

Design is where your oven takes shape.

“It’s not just a model. It’s the future of your company. It has weight to me.”

—Dan Kelly, Design Engineer, Grieve