High Temperature Bench Ovens

High Temperature Bench Ovens

Designed to fill the need for economically priced ovens for high temperature processes, such as tempering and stress relief. Easily moved to various locations for processing large parts, baking, drying components after cleaning, dehydration, preheating, curing and other applications requiring circulation of heated air.

High Temperature Bench Ovens Model Specifications:

Not for use with flammable solvents, vapors, or gases. Other models available for these applications.

| Model | Workspace | Outside Dimensions*(WxDxH) | Max Temp | Blower | Heat Input | Insulation Thickness | Operating Characteristics† | Approx Shipping Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions(WxDxH) | VolumeCu Ft | CFM | HP | ElectricKW | GasBTU/HR | Control Accuracy | Temperature Uniformity | Rise Time (Electric) | Rise Time (Gas) | |||||

| NT-800 | 26" x 22" x 13" | 4.3 | 39.5" x 34" x 30" | 800°F | Not Available | NA | 2.4 | Not Rated | 4" | ± 0.5% | ± 20°F | 60 | Not Available | 310 lbs |

| NTR-800 | 26" x 22" x 13" | 4.3 | 39.5" x 34" x 30" | 800°F | Not Available | NA | 2.4 | Not Rated | 4" | ± 0.5% | ± 15°F | 55 | Not Available | 310 lbs |

| NT-1000 | 26" x 22" x 13" | 4.3 | 41.5" x 35" x 31" | 1,000°F | Not Available | NA | 2.4 | Not Rated | 5" | ± 0.5% | ± 25°F | 105 | Not Available | 335 lbs |

| NTR-1000 | 26" x 22" x 13" | 4.3 | 41.5" x 35" x 31" | 1,000°F | Not Available | NA | 2.4 | Not Rated | 5" | ± 0.5% | ± 20°F | 95 | Not Available | 335 lbs |

† Outside Dimensions

- Click here for NT-800_NTR-800_NT-1000_NTR-1000 dimensions

- Heat input footnote:

- Specification chart above utilizes 115V; for 208 & 230 volt — heat input is 3.0 kW

† Operating Characteristics

- Accuracy as percent of controller span.

- Uniformity at 50°F below maximum temperature.

- Rise Time in minutes to 50°F below maximum temperature.

- Tests run with empty oven and minimum exhaust.

- Performance will vary with load and application.

- See Control & Instrumentation Summary for additional details.

Specifications for High Temperature Bench Ovens

| MODEL | NTR-1000 |

|---|---|

| MAXIMUM OPERATING TEMP | 1,000°F |

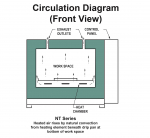

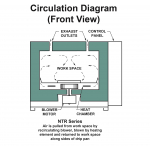

| AIR FLOW | Bottom to Top, Forced Convection |

| CONTROL ACCURACY | ± 0.5% |

| OVEN UNIFORMITY | ± 20°F |

| RISE TIME - ELECTRIC | 95 mins |

| RISE TIME - GAS | Not Rated |

| WORKS SPACE DIMENSIONS (WxDxH) | 26" x 22" x 13" |

| SHELVES INCLUDED | 2 |

| NUMBER OF SHELVES MAX | 6 |

| SHELF CAPACITY | 20 |

| MAX LOAD CAPACITY | Not Available |

| DOORS | Manual |

| LOADING METHOD | Shelf |

| APPROXIMATE SHIP WEIGHT | 335 lbs |

| OUTSIDE DIMENSIONS (WxDxH) | 41.5" x 35" x 31" |

Standard Features for High Temperature Bench Ovens

Certifications

- Meets the Requirements of the Following Standards:

- NFPA 86 (Standard for Ovens and Furnaces)

- NFPA 70 (National Electric Code)

- OSHA

- Caution:

- When processing combustible material fire protection should be considered

- Processing flammable solvents or vapors requires forced exhaust to provide safety ventilation. For more information see Class A Solvent Processing page at this website

Safety Equipment

- Adjustable manual reset excess temperature interlock to turn off heat on malfunction of main temperature controller

- Separate heating element control contactors to turn off heat on malfunction of main control contactors

Controls

- Analog non-indicating temperature controller

- Red pilot light to indicate heater operation

- On-Off switch

Construction

- 115 volt, 208 volt, 230 volt or 460 volt, 1-phase, 50-60 HZ- other input power available

- 3-wire cord with plug on 115 volt models requires 30 ampere 115 volt service

- 3-wire cord only on 208 and 230 volt models

- 460 volt models incoming power hardwired to control panel

- Durable, electrically isolated, Incoloy tubular heating elements

- Shelves adjustable on 2” centers

- Stainless steel shelves on 1000⁰F models

- Insulated with 6 lbs per cubic foot density rockwool insulation

- 304 stainless steel interior with plated hardware

- Brushed stainless steel exterior

- Fiberglass door gasket with stainless steel spring insert

- Fully assembled and factory tested

- 1 year limited warranty

Modifications & Accessories for High Temperature Bench Ovens

-

Bench Oven Shelf

Oven accessory adding an additional shelf with a maximum distributed load of 20 lbs.

-

Bench Oven Stand

Oven modification adding a Bench Oven Stand that raises a unit to a convenient 31″ work level.

-

Digital Indicating Temperature Controller

Oven modification adding a Digital Indicating Temperature Controller. Microprocessor based, thermocouple actuated, in lieu of standard controller.

-

Programmable Temperature Controller

Oven modification adding a programmable Temperature Controller. Microprocessor based, digital indicating, thermocouple actuated, in lieu of standard controller.

-Program Parameters: 40 profiles of up to 50 steps each, a real-time clock with battery backup to allow starting profile at any time of day

-Digital Display, 4.3” color touch screen

-Accuracy, ±0.1% of span plus 1 degree display error

-Connectivity, Relay output for alarm or other notification, two (2) USB ports, Ethernet compatible

Also Available:

-Up to four (4) control channels of temperature, relative humidity or vacuum

-Monitor up to16 sensors

-Math and logic functions

-Digital inputs and outputs

-Data logging

-Graphic Trending

-

Digital Timing Temperature Controller

Modification adding a Digital Timing Temperature Controller. Microprocessor based, incorporates 99 hour 59 minute timer, starts timing temperature reaches set point and shuts down oven at end of set time.

- Digital Display, two LED, alphanumeric, 4 digit displays; 0.875″ high for temperature display and 0.500″ high for set point display

- Accuracy, ±0.1% of span plus 1 degree display error

-

Recording Thermometer

Accessory adding a Recording Thermometer. Thermocouple actuated.

- Record: 10″ diameter circular chart 24 hour chart rotation

- Digital Display: 0.56″ high, LED, alphanumeric, 4 digit display; LED status display

- Accuracy: ±0.25%of span plus 1 degree display error

-

Solid State Relay

Oven modification adding a Solid State Relay in lieu of mechanical heater contactor.

-

60 Minute Shut Down Timer

Oven modification adding a Shut Down Timer. Shuts down oven, 60 minute range, continuous “hold” feature.

-

12 Hour Shut Down Timer

Oven modification adding a Shut Down Timer. Shuts down oven, 12 hour range, continuous “hold” feature.

Custom Ovens

-

Model NTR-1000 High Temperature Bench Oven

Serial #: 451980Double pane window in door and stand.

- MAX TEMP: 1000ºF

- WORKSPACE DIMS (WxDxH): 26" x 22" x 13"